Epoxy Floor Coating

Epoxy flooring, also known as resinous flooring or polymer flooring, is a two-part mixture consisting of resin and hardener. Epoxy is placed over concrete, wood, VCT, tile, or any other common industrial and commercial floors. The chemical reaction creates a bond to the substrate and forms a hard plastic. can be applied the thickness by a maximum of 500 microns. The uses of epoxy coating are

- Parking

- Warehouses

- Industrial Areas

Self-Level Epoxy Coating

Self-leveling epoxy is a coating applied to a slab of concrete and, as the name suggests, it's easy to apply because it self-levels and spreads out across the flooring surface. It quickly creates a single seamless surface across the floor. can be applied the thickness by a maximum of 2 mm - 4 mm. The uses of epoxy coating are

Our masterful team at BJC is primed to execute your needs no matter the complexity, scale, scope, or scene big or small. Commercial or personal. Local or global. We are committed to those who trust our combined decades of expertise and eclectic experience. Realize the unified lifestyle that you desire. In collaboration with our international web of artisans, BJC will orchestrate, manage and deliver your interior from its creative conception to the project's completion.

- Industrial Productions Lines

- Commercial Buildings

- Hygienic Facilities

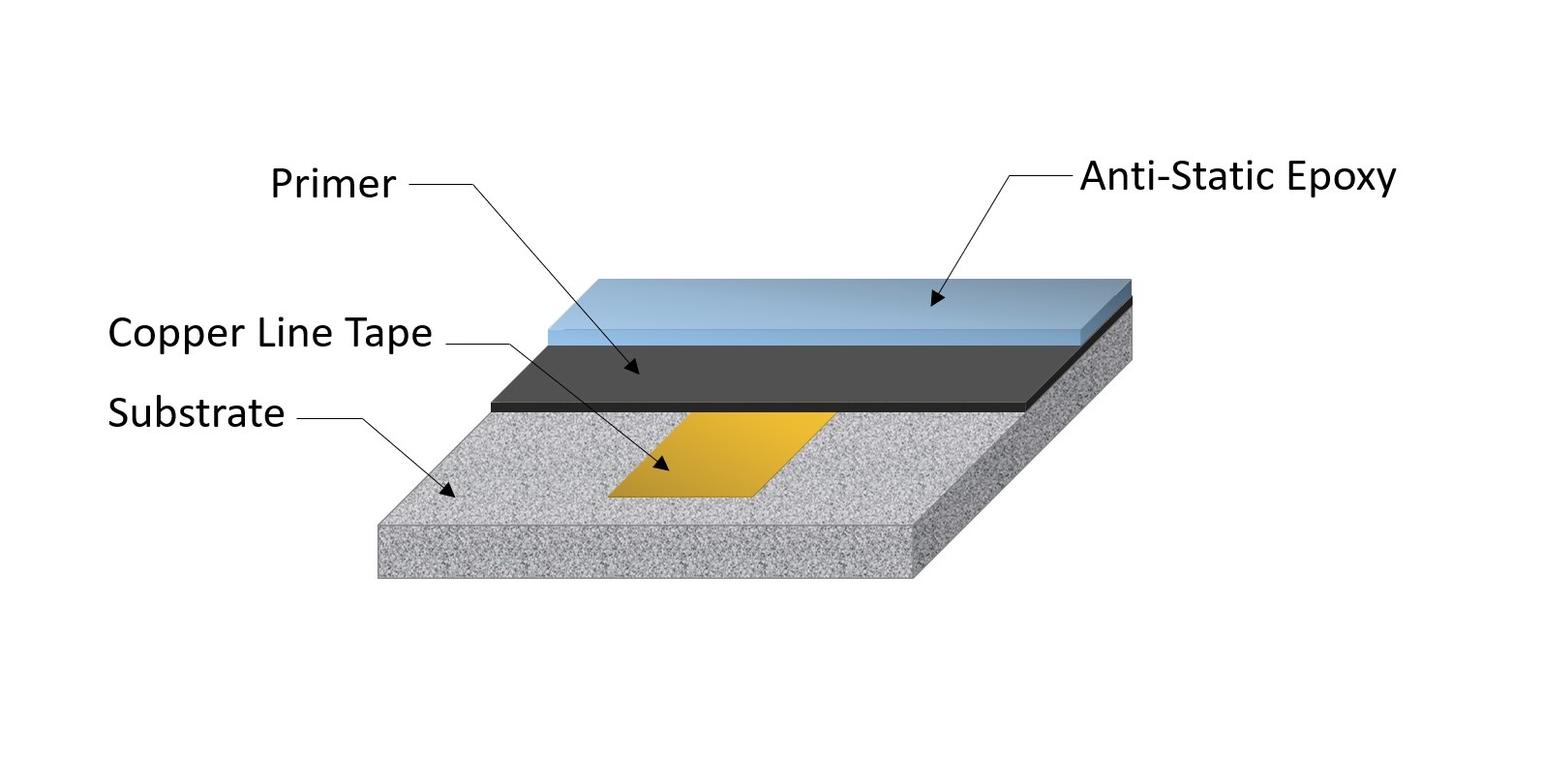

ANTI-STATIC & CONDUCTIVTIY FLOORING

Anti-static industrial floors inhibit the generation of electrostatic discharge or ESD, which is the pulse of static electricity that happens when a charged person or surface comes into contact with another object. The discharge may be visible as a spark or tiny blue bolt of electricity, although the majority of static electricity is not usually apparent, and these sparks may be very dangerous in some industries. can be applied the thickness by a maximum of 1,000 microns. The uses of epoxy coating are

- Military Industries

- Electronic Factories

- Digital Communications Rooms

Outdoor Floor Coationg

Anti-static industrial floors inhibit the generation of electrostatic discharge or ESD, which is the pulse of static electricity that happens when a charged person or surface comes into contact with another object. The discharge may be visible as a spark or tiny blue bolt of electricity, although the majority of static electricity is not usually apparent, and these sparks may be very dangerous in some industries. can be applied the thickness by a maximum of 1,000 microns. The uses of epoxy coating are

Our masterful team at BJC is primed to execute your needs no matter the complexity, scale, scope, or scene big or small. Commercial or personal. Local or global. We are committed to those who trust our combined decades of expertise and eclectic experience. Realize the unified lifestyle that you desire. In collaboration with our international web of artisans, BJC will orchestrate, manage and deliver your interior from its creative conception to the project's completion.

- Military Industries

- Electronic Factories

- Digital Communications Rooms

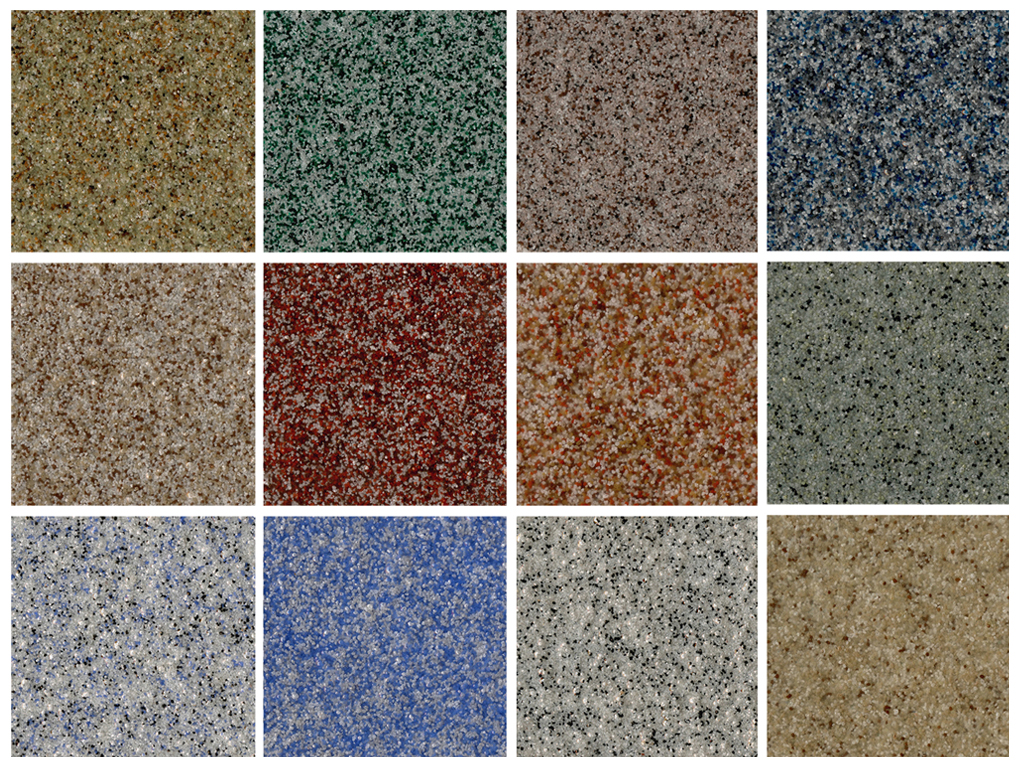

Epoxy Flakes Coating

Epoxy Flake Coating is an anti-slip method that spreads a layer of Epoxy chemicals on the floor before adding colored flakes on top as a way to create texture and patterns. These Epoxy chemicals include a resin material and a hardener that has to be blow-torched to fuse and create a new surface. Also, it comes in various colors. can be applied the thickness by a maximum of 1100 microns. The uses of epoxy coating are

Our masterful team at BJC is primed to execute your needs no matter the complexity, scale, scope, or scene big or small. Commercial or personal. Local or global. We are committed to those who trust our combined decades of expertise and eclectic experience. Realize the unified lifestyle that you desire. In collaboration with our international web of artisans, BJC will orchestrate, manage and deliver your interior from its creative conception to the project's completion.

- Private Garage Floor

- Bio Labs

- Applicable for decorative (Commercial)

- Applicable for decorative (Residential)

Quartz Broadcast Epoxy

Quartz (4 grit sizes) is a low-cost anti-slip for a more aggressive anti-slip protection. It is a heavier additive that is typically broadcast into the topcoat while wet and then back rolled so it is encapsulated by the coating. It is also more visible and harder to clean than the SSR-20. It is most common. And also, it comes in various colors. can be applied the thickness by a maximum of 1000 microns. The uses of epoxy coating are

- Commercial Buildings

- Industrial Buildings

- Where is the slip resistance required

Metalic Epoxy Flooring

A metallic epoxy is a form of solid epoxy that has metallic, glitter-like particles embedded in it. When properly mixed and applied, the result is an extremely distinctive and eye-catching effect with what appear to be three-dimensional shimmering swirls throughout the flooring. Plus, it’s reflective, which makes it look even more interesting.

It is most common. And also, it comes in various colors. can be applied the thickness by a maximum of 1000 microns. The uses of epoxy coating are:

- Showrooms

- Offices

- Lobby

- Applicable for decorative (Commercial)

- Applicable for decorative (Residential)

Urethane Cement Slurry

Urethane componentry is a three-component, thermal shock resistant, urethane slurry (broadcast optional), extremely durable flooring system. Available in a variety of colors and engineered to be FDA, USDA, and CIFA acceptable for applications in food manufacturing, packaging, and serving facilities. This flooring system is engineered to withstand forced steam cleaning daily, along with its resistance to bacterial growth makes it ideal for most food and beverage manufacturing and serving facilities. Non-slip when wet, will withstand severe traffic exposure. also, it comes in various colors. can be applied the thickness by a maximum of 6 mm - 10 mm.

- All food & beverage industries

- Meat/poultry & dairy processing

- Breweries & Wineries

- Pharmaceutical plants

- Commercial kitchens & restaurant

- General warehouse & manufacturing facilities

- Fire, rescue & EMS

- Marijuana dispensary, grow & retail

- Automotive service bays

- Cold storage facilities

TERRAZZO FLOOR

Terrazzo flooring is a popular option for several reasons – the flakes create a beautifully textured surface, reflecting light in a way that can imitate marble, quartz, or any number of high-quality finishes. With the development of the epoxy variation of traditional terrazzo flooring came a whole new range of color options, and the style became less expensive and more accessible to a wider population.

Epoxy terrazzo is also popular because different segments of the floor can be divided by strips of metal and given different colors to create beautiful patterns or delineate various areas. Differently colored shapes and figures can also be installed by bending the metal dividers into the desired shape. also, it comes in various colors. can be applied the thickness by a maximum of 6 mm - 10 mm

- Airports

- Showrooms

- Offices

- Hospitals

- Restaurants

- Hotels

Stone Carpet

Stone carpet flooring, a resin-bound surfacing is a cold applied clear Polyurethane resin screed designed to bind a range of natural stones in a range of colors. Decorative resin-bound stone carpet flooring is suitable for use internally or externally. also, it comes in various colors. can be applied the thickness by a maximum of 6 mm - 10 mm

- Parks

- Walkaway

- Hardscape for Residential and Commercial Buildings

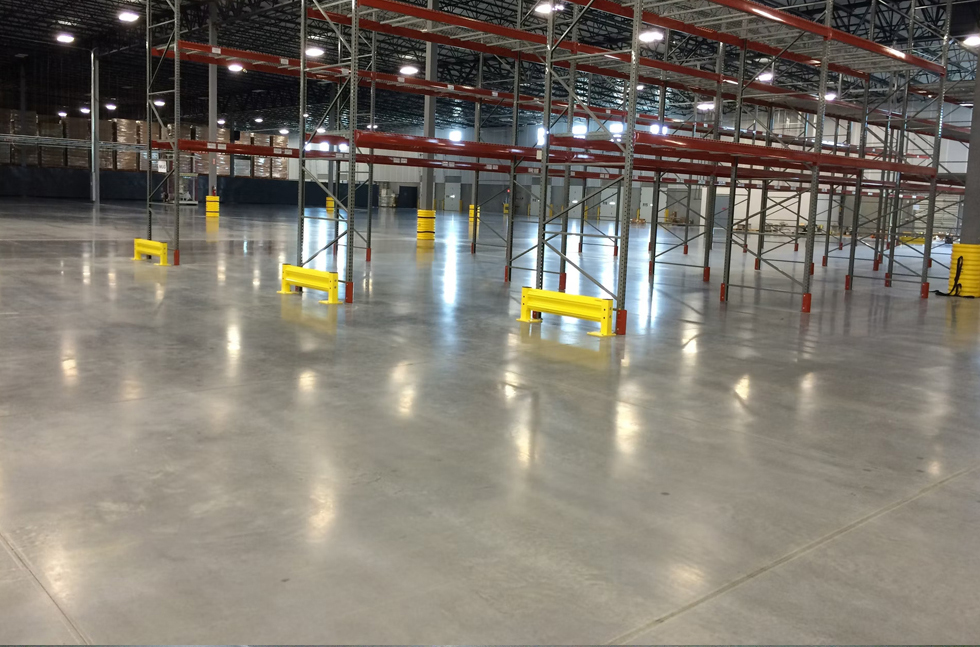

Polished Concrete

Polished concrete is a multi-step process where a concrete floor is mechanically ground, honed, and polished with bonded abrasives to cut a concrete floor's surface. It is then refined with each cut to a specified level of appearance.

This process also includes the use of a penetrant chemical known as a hardener. The concrete densifier/hardener penetrates the concrete and creates a chemical reaction to help harden and dust-proof the surface. During concrete polishing, the surface is processed through a series of steps (in general a minimum of four grinding steps of processing is considered polished concrete) utilizing progressively finer grinding tools. The grinding tools are progressive grits of industrial diamonds in a bonded material such as metal/hybrid/resin often referred to as diamond polishing pads. Polished concrete is a "green" flooring system and LEED approved. Concrete is not considered polished before 1600 grit, and it is normally finished to either the 1600 or 3000+ grit level. Dyes designed for concrete polishing are often applied to add color to polished concrete as well as other options such as scoring, creating radial lines, grids, bands, borders, and other designs. Any grinding under 1600 grit is considered a honed floor.

- Airports

- Showrooms

- Offices

- Hospitals

- Hotels

- Restaurants